Heat Exchangers

Cembell has over 40 years of experience in every aspect of the design, fabrication, and repair of all types of heat exchangers.

Thermal & Mechanical Design of heat exchangers with HTRI, RCS, and CodeCalc. Complete fabrication per ASME Sec. VIII, Div 1 & Div 2.

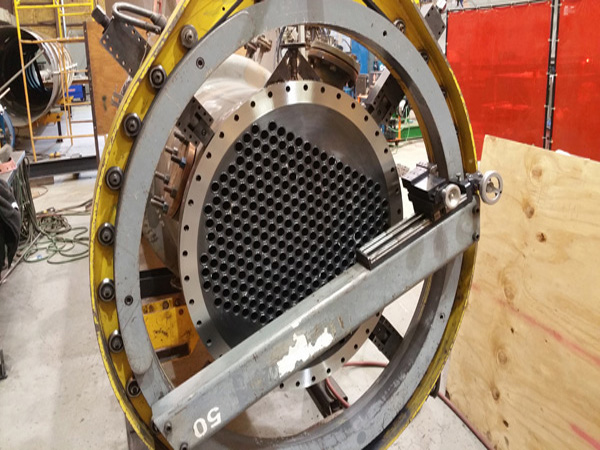

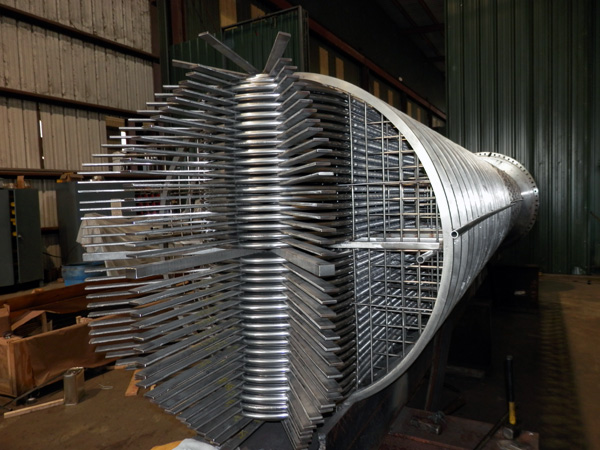

- Shell & Tube Exchanger fabrication

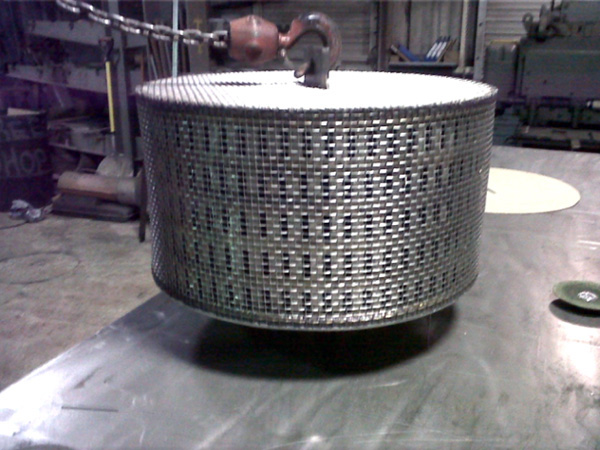

- Rod Baffle Exchanger fabrication

- Re-tubes with tubesheet and bundle repairs

- Tube plugging

- Channel head, nozzle, and shell inspection, repair, and replacement

- Testing (Hydro, Helium, Vacuum, and Static Air)

- All tube and tubesheet coatings; both preventative and restorative

- On-site sand blasting, painting, and coating

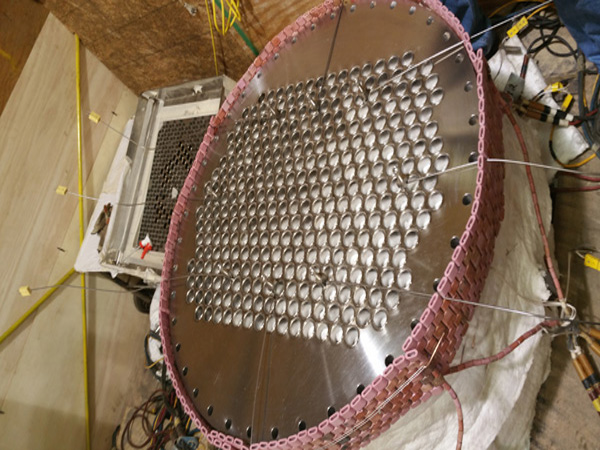

TUBE-TO-TUBESHEET WELDING

Cembell specializes in tube-to-tubesheet welding. Does your application require a welding mock-up? No problem. With over 125 successful tube-to-tubesheet mock-ups, we can handle just about all your

tube-to-tubesheet configurations.

Mock-ups include, but are not limited to:

- Strength welding: Alloy 20, C276, 2205, Monel 400, Nickel 200, AL6XN, 90/10 Cu/Ni

- Seal welding: Titanium, Zirconium, Alloy 2205

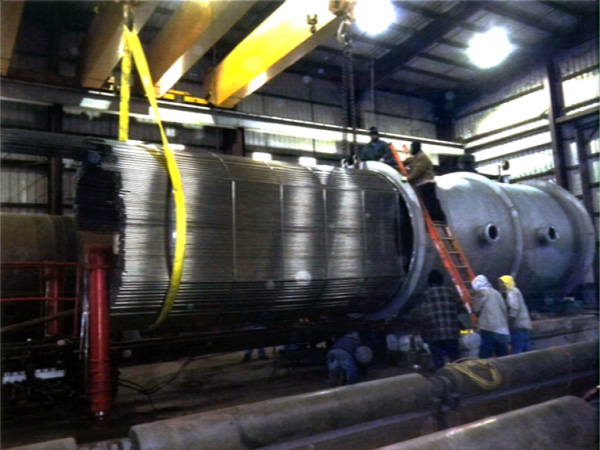

Duplex Exchanger with 14,000 tubes being stabbed in shell

317L Stainless Steel U-Bundle

Rod Baffle Exchanger cage ready for installation of tubes

90 inch ID x 50 ft long Heat Exchanger weighing 295,000 lbs